Hydrogen supply to the jobsite

Jean-Baptiste Martin, responsible for hydrogen development and industrial applications for French perimeter at TotalEnergies, introduced the company’s 2030 and 2050 decarbonization objectives, which target 50% sells of renewable electricity by 2050.

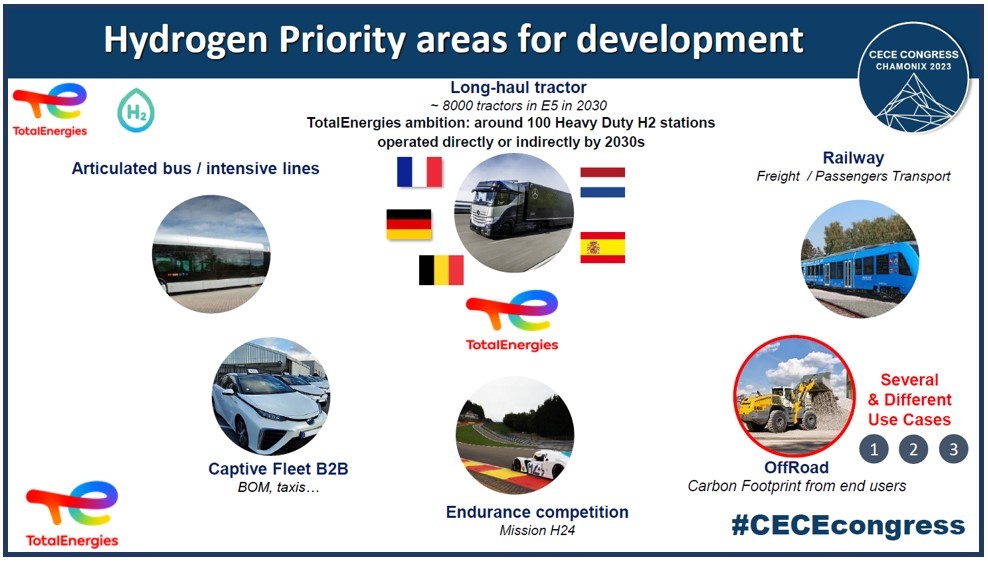

Jean-Baptiste presented an overview of the research and development carried out by TotalEnergies in the last 20 years to support the implementation of H2 solutions in mobility. This included the development of refueling stations and the recently presented collaboration with Liebherr for the development of the hydrogen-powered crawler excavator. Indeed, TotalEnergies represents today in 2023 up to 33 stations in Europe in France, Germany, Belgium, Netherlands and cofounded a joint venture H2Mobility for H2 in Germany with the aim of covering not only passengers cars, but also heavy duty vehicles in a new phase. TotalEnergies aims to be a reference player of the H2 energy distribution, low carbon or renewable for heavy transport with an ambition of around 100 H2 stations operated directly or indirectly in the next decade in Europe.

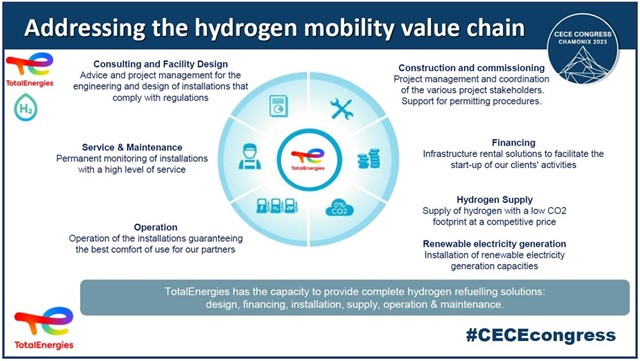

With a holistic approach, TotalEnergies addresses the full hydrogen mobility value chain for refueling solutions: from the consulting and facility design to the construction itself, financing and service and maintenance. Jean-Baptiste pointed that non harmonized regulation across Europe for the refueling station is one of the main concerns for a quick development; creating a need for tailor made solutions, not only a nation level but even a regional one.

Another important challenges are the development of fast refueling, crucial also for machinery and the high pressure storage.

Focusing on the construction jobsite, the complexity increase and the solutions are strongly dependent on the process use case. Jean-Baptiste illustrated with three examples this of situations: 1. the long-term site operation such as pit stone with a particular ecosystem normally composed by 2-8 machines that will require a high demand of hydrogen but with stable operation conditions with the possibility of a fix model station.

A second example was an urban zero emissions jobsite with few months fix operation and that would require a mobile temporary hydrogen refueling solutions. The challenges in this case are the fuel supply and storage. The third case was a temporary worksite (e.g highway building) where the refueling system is a mobile station; in this last case the with the difficulties to solve are about the transfer of fuel and the optimization of the conditions and capacity of the fuel tanks.

Finally Jean-Baptiste Martin listed the conditions for a high-level technical solution ‘HY-CARE already available and in operation for customers : «Hydrogen as a service” with a format that simplifies operations: it has to be multi-segments, it means stations with Dual Pressure of 350 and 700 bar, high capacity and highly flexible system to be transportable and deployable in 4 to 6 weeks. This solution would provide 200kg/d to refuel per day for instance fleet of 5 trucks, or 10 buses, or 15 dumpsters or even 50 light commercial vehicles.

Go back to the Technical Bulletin